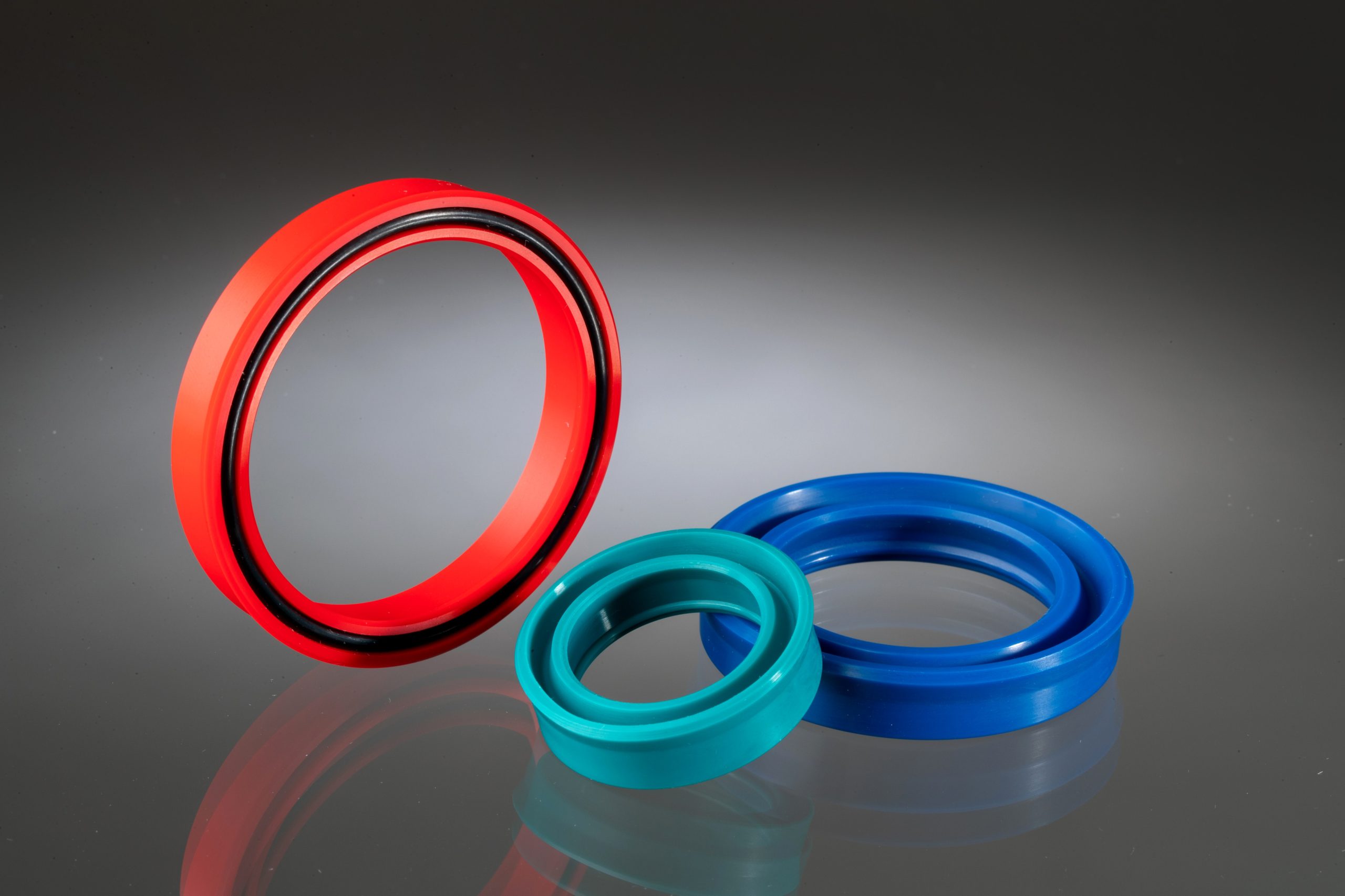

Hydraulic Seals

Hydraulic seals & Pneumatic seals are designed as per the cylinder working pressure, cylinder speed, operating temperature, working medium and application

Hydraulic Seals

Hydraulic seals are generally relatively soft, non-metallic rings captured in groove or fixed in a combination of rings, forming a seal assembly, to block or separate fluid in reciprocating motion applications. Hydraulic seals are vital in machinery. Their use is critical in providing a way for fluid power to be converted to linear motion.

Hydraulic seals can be made from a variety of materials such as polyurethane, rubber or PTFE. The type of material is determined by the specific operating conditions or limits due to fluid type, pressure, fluid chemical compatibility or temperature.

A static hydraulic seal is located in a groove and sees no movement – only sealing within its confined space, acting like gasket.

A type of dynamic hydraulic seal called a rod seal is exposed to movement on its inner diameter along the shaft or rod of a hydraulic cylinder. A type of dynamic hydraulic seal called a piston seal is exposed to movement on its outer diameter along the tube or bore of a hydraulic cylinder.

Piston Seals

Hydraulic Piston Seals seals ensure fluid or other media does not by-pass the piston as the system pressure pushes the piston down the cylinder during a pressure cycle.

Piston seals are dynamic seals, typically single-acting (pressure acting on one side only) and double-acting (pressure acting on both sides) seals. The choice of piston seal is determined by the way in which the cylinder operates.

Read More.

Rod Seals

Rod seals are considered the most critical element of a cylinder sealing system. They prevent the leakage of fluid from within a hydraulic cylinder to the outside as the rod cycles back and forth (dynamic pressure sealing). Rod seals work together with wiper seals to protect a hydraulic system against external contaminants such as dirt and outside weather conditions.

Rod seals are static seals installed in the glands or housings. They maintain a seal with the piston rod in dynamic motion.

Read More.

Wiper Seals

Wiper seals are also known as Scraper seals. They tend to be used in conjunction with other sealing elements. Wiper seals create a tight fit whilst still allowing a reciprocating ram rod to pass through the inner bore of the seal. Despite it’s important function, the wiper seal is possibly the most undervalued seal type in the hydraulic cylinder.

Read More.

Wear Rings

Wear rings are used to help keep the piston centred, which allows for even wear and pressure distribution on the seals. These seals are used in both piston and rod applications. Popular wear ring materials include glass filled Nylon, bronze filled PTFE and glass filled PTFE. Wear rings are available in butt cut, angle cut and step cut styles.

Read More

Eastern Seals’ Hydraulic & Pneumatic range caters for the full range of duty cycles. Typical applications covered are cylinders, mobile cylinders, hydraulic presses and moulding machines.

We can supply seals for single and double acting cylinders, compact seals and composite piston seals, symmetrical seals, independent wear rings, bonded seals and static seals, such as O rings.

Part of our Hydraulic range includes telescopic seals.

Eastern Seals UK Ltd offer a range of seals especially suited to pneumatic applications. Our products are formulated to give optimum properties including, ultra long life, ultra low friction, water resistant and wide temperature capability.

REQUEST A CALLBACK

If you have any queries, or would like any more information,

don’t hesitate to get in touch

Online store

We are the largest supplier of British Standard, Metric series O-rings and sealing solutions.

Visit Store Now